What do you know about vacuum metalizing? Whether you’re familiar with or have never heard of the process, you probably come across it practically every day. Below, we’ll explain what vacuum metalizing is and its benefits.

While you may have never heard of the vacuum metalizing process, you’ve almost undoubtedly come across a product or electronic that utilizes the process. Many of these items are common in everyday life. Vacuum metalizing is a form of physical vapor deposition. Basically, it’s the process of coating a non-metallic substrate with a metal coating via evaporation.

There are many materials people use for vacuum metalizing. However, the most common material across many applications is aluminum. With a metal coating via vacuum metalizing, a non-metallic material like plastic can gain metallic properties, including electrical conductivity, moisture barriers, and a reflective appearance.

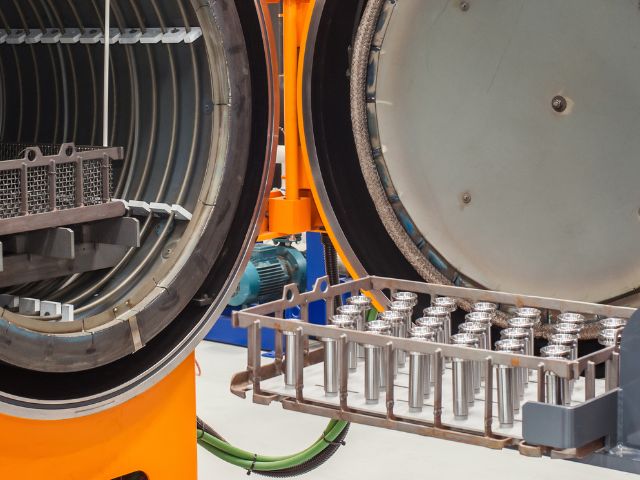

While vaporizing a metal substance to coat a substrate may seem extraordinary, the process is remarkably simple. The process takes place in an enclosed chamber with a pressurized vacuum. Inside the chamber, the liquid metal material changes from a condensed liquid to a vaporized material.

After this, the material vapor undergoes pressurization so that it adheres to the surface of the substrate to produce a uniform metal coating. Since it all takes place in an enclosed chamber, vacuum metalizing has no environmental or health risks.

Vacuum metalizing has many uses for many industries. It can be functional and decorative. Aesthetically, vacuum metalizing a substance will give it an eye-catching, shiny appearance without the entire material being an expensive metal. Practically, vacuum metalizing has many applications, especially for insulation.

The aerospace industry uses vacuum metalizing frequently to coat lightweight materials on aircraft and spacecraft, such as plastic components, with metal to absorb and reflect electromagnetic waves. Vacuum metalizing helps provide the properties of metal materials without the weight. The process also frequently helps create metallic coatings for automotive parts.

We’ve explained vacuum metalizing, but what are its benefits, and why is it so common in so many industries? Whatever its application, vacuum metalizing is always a cost-effective option for creating a uniform and practical metal coating quickly and efficiently.

And compared to other metal coating processes, such as chromium plating, vacuum metalizing doesn’t require a mixture of hazardous chemicals and materials like cyanide and chromium. Therefore, it’s also a much safer process. For industries that want to apply metallic properties to non-metallic substrates, vacuum metalizing is ideal.

The next time you see a piece of jewelry with a metallic coating or fly on an aircraft, you’ll know you’re experiencing firsthand the benefits of vacuum metalizing.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com